Freeform gelatin microfluidics

In late 2015, Hinton et al. (see full article) published a widely cited article describing a method for freeform reversible embedding of suspended hydrogels, or FRESH for short. In summary, it allows precise deposition of material inside a gelatin matrix, which offers support for the printed material and consequently allows the fabrication of almost any shape or form. The matrix itself is made from finely ground and washed gelatin granules in a way, such that the already deposited material is not affected by further movement of the nozzle. The base is infused with Calcium ions, thus ion-polymerising gels such as alginate (which can be mixed with live cells) are encapsulated and cross-linked directly upon deposition. After printing, the solidified structure can then be liberated from the matrix. Freeform bioprinting - done!

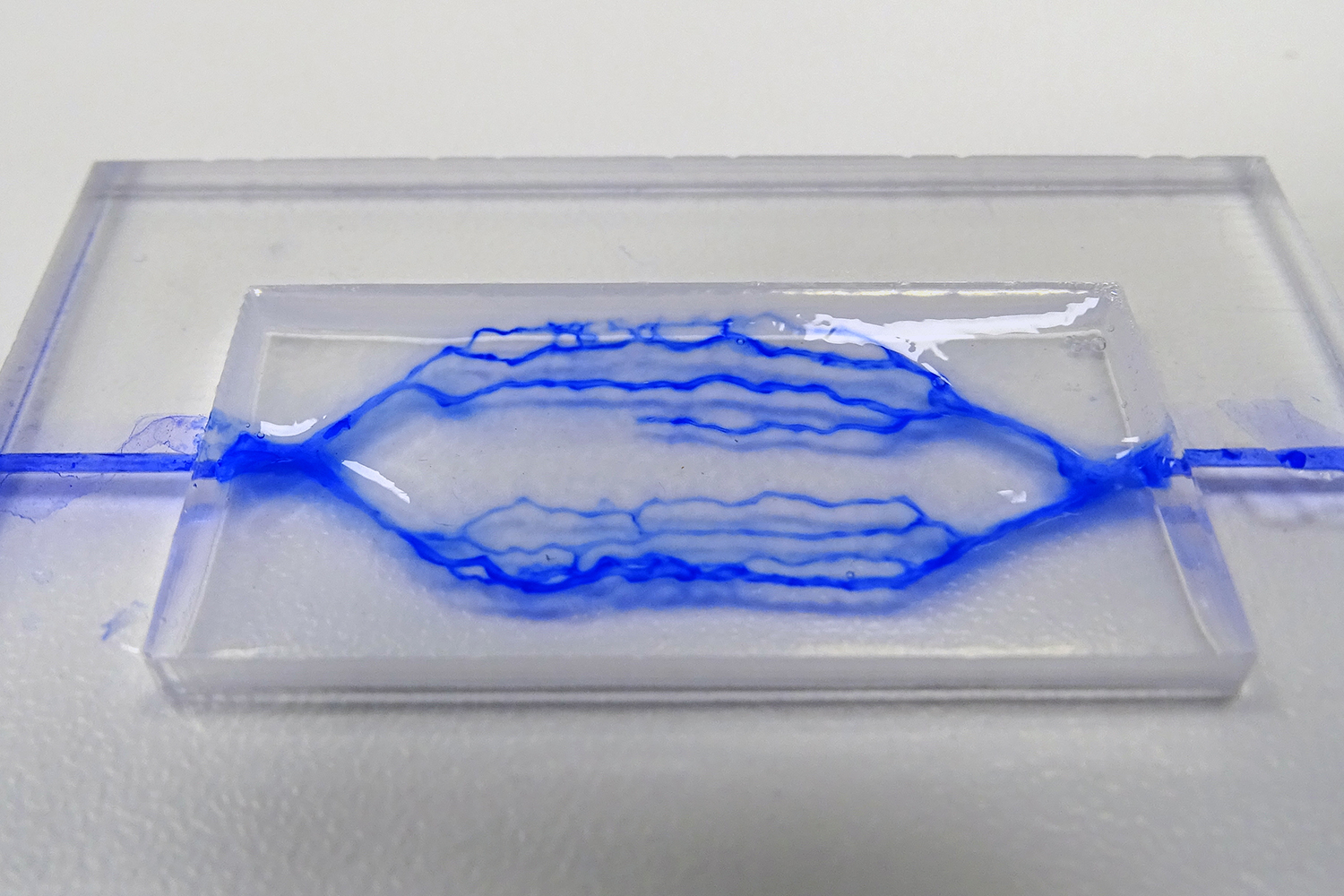

For members of our Symbiolab, this study has sparked the idea of creating freeform microfluidic channels inside the gelatin matrix with our Vitaprint 3D bioprinter. This could be used for creating thick, perfusable tissues and act as a foundation for creating vascularised tissues. In highly metabolic tissues (i.e. gut, liver, brain, etc.), every cell needs to be less than 100 μm away from a blood vessel. Thus, vascularisation is a huge deal in tissue engineering and remains the main obstacle in creating thick functional tissues. The Methuselah Foundation and NASA are even cosponsoring a 500 000$ prize for the first team to sucessfully fabricate a 1 cm high functional tissue, that can survive for a month. The first experiments at our lab have been surprisingly successful and we hope to publish the results in the form of a scientific article soon, so be sure to stay tuned…