Accuracy consideration for different drilling methods

Since the accuracy of drilling and locating the center of the holes is crucial in the construction of CNC plasma cutting machine and CNC milling machine, we decided to make a short guide on how to drill holes correctly. At the same time, we have tested various processes of drilling holes and measure and evaluate the given results. We chose three manufacturing processes for drilling through both walls of the rectangular profile - an element often used in structures of our CNC plasma and milling machine:

- Drilling holes directly with the end 8 mm drill bit, from one side through both walls,

- Drilling holes using pre-drill with 2.5 mm drill from one side through both walls, followed by drilling with the end 8 mm drill bit, from one side through both walls,

- Drilling holes using pre-drill with 2.5, 5.5 and 6.5 mm drill from both sides, followed by drilling with the end 8mm drill bit, from both sides of each wall separately.

Tools we used: scribe for marking lines and center of the holes, basic rules, machinist’s square, center punch and amateur drill press.

Using those three systems for drilling holes we were given following results:

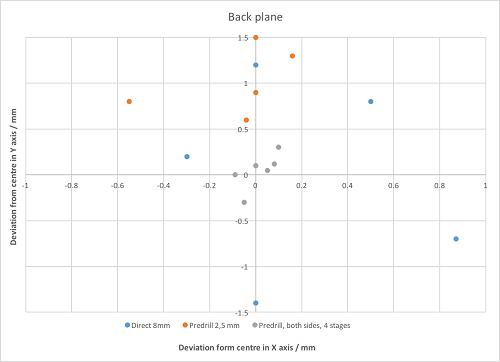

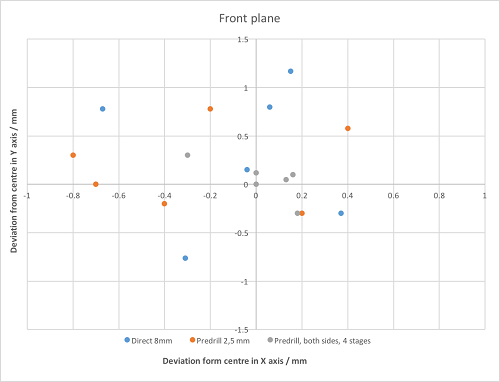

Results are displayed on graphs, showing the distance from the hole to the original center position. Graphs are representing deviances from centre on the front and back plane of profile.

Average deviation from centre

Front plane: Direct 8mm – 0.46 mm Pre-drill 2.5 mm through – 0.41 mm Pre-drill both sides, 4 stages – 0.14 mm

Back plane: Direct 8mm – 0.69 mm Pre-drill 2.5 mm through – 0.77 mm Pre-drill both sides, 4 stages – 0.15 mm