GoodEnoughCNC – some good and some not-so-good news

First, some good news – we’ve made several improvements to our GoodEnoughCNC Hybrid, which are simplifying the design and making the machine more robust.

Z axis: We completely changed the structure of the Z axis. Instead of the axial bearings used for railing system we decided to use a linear bearing with casings, which makes the axis sturdier and much more accurate. We replaced the M8 rod used for linear movement of the Z axis with a ball screw and an anti backlash nut with 4 mm pitch, further increasing the accuracy of the whole system, enabling finer movement and longer lifetime. The base plate is now made out of 5 mm aluminium plate, which also increases the structural strength.

Tightener: We made some minor changes to the tighteners, mostly reducing parts count and enabling easier installation. The tightener bracket is now a one piece laser cut part made out of tubular stainless steel profile. We also replaced the nuts with a screwing tightener with threads already implemented into the model.

Beam short for trolley assembly: We added inspection holes used in mounting process of the ball bearings, which help with accurate placement of the ball bearings.

Technical documentation is already uploaded in the folder HybridCNC_v3 of our Github repository and ready for you to use.

However, we also have a not-so-good announcement to make.

During last year we have explored how to take GoodEnoughCNC project onwards and transform it into sustainable business, from on-location workshops to selling kit version of the machine.

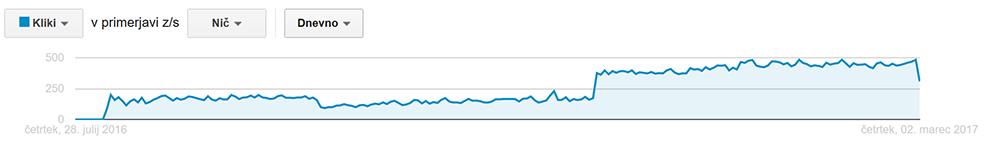

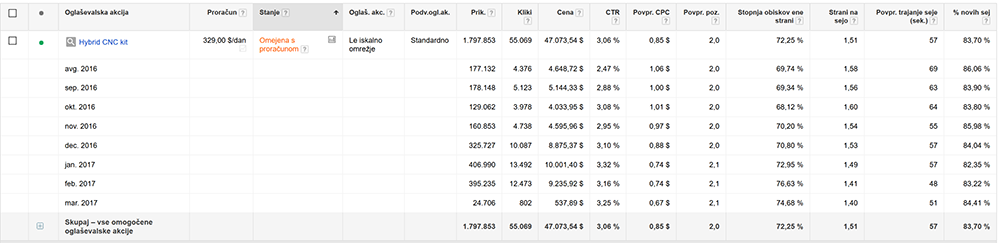

From August 2016 to February 2017 we were also running a Google for Nonprofits Adwards campaign, with which we were promoting our open source HybridCNC kits. During that time we received 1.797.854 impressions and 55.096 clicks, with a click through rate of 3,06 %. In the second half of 2016 we sold 10 HybridCNC suitcase kits, held 1 workshop on the location and one online workshop. After depleting the stock in the end of November, we kept the pre-orders for kits opened; without specific marketing efforts dedicated to a new version coming out, but with the old Google Adwards setup running. In that time period we’ve received one paid pre-order and 59 registered interests for buying a new version.

After receiving quite some email enquiries for this project from individuals coming from the developing part of the globe, we also made a step towards optimizing HybridCNC for developing contexts. We held several conversations with organizations active in post disaster relief zones and developing countries (among others Field Ready – organization providing humanitarian supplies made in the field using the latest technology including 3D printers and laser cutters as well as passing on these skills to others through trainings, Kumasi Hive - startup incubator, makerspace, co-working space and inovation hub based in Kentinkrono, Kumasi, Ghana, Humanitarian Makers - organization supporting locally-led design and production of hardware solutions to humanitarian challenges, Tech for Trade - organization supporting sustainable and scalable technology innovations that facilitate trade and alleviate poverty) and learnt that there exists a need and an interest for digital fabrication solutions, but all the organizations we talked to have no existent capacities to buy our technology and work with it on the field by themselves. Everyone interested would require a significant financial contribution and our active involvement on the ground to be able to run the pilot. In order to take this project onwards and be able to proof the social impact of GoodEnoughCNC for developing contexts we ourselves would need to move to the field. For the time being this kind of involvement goes well beyond the current institute’s scope though.

After having all the feedback on the table we concluded that with a present setup we are not receiving sufficient interest to run this project at sustainable levels. It is true that GoodEnoughCNC was never our institute’s primary focus, but facing the time and people constraints also in the near future we wouldn’t be able devote enough capacities to product development, service improvements and marketing efforts, which are needed to run the project with desirable results.

With all that said, we have decided to put the project into sleep mode, which means we’ll no longer actively develop GoodEnoughCNC, manufacture and sell the kits or offer support. Of course, all the documentation will remain published online in an open source fashion for everyone interested to make this project in a DIY manner. In case the circumstances significantly change we are definitely ready to rethink our decision. For now, however, all our focus is moving to Koruza and the open hardware development and manufacturing collaborations with outside partners.