A new year of developing open hardware for applied systems is ahead of us with the success of Shuttleworth Fellowship application

We are really excited and proud our founder Luka Mustafa became a Shuttleworth Fellow for the third year and want to congratulate him at this occasion. Together we will continue our work of building sustainable operations in the long run and support our efforts towards creating a paradigm shift in how we develop, manufacture and use technologies.

For the past 2 years as Shuttleworth Fellow Luka has been exploring the vision of open hardware, creating operational and useful devices. Over this time his thinking has evolved from almost a utopian perspective of following open licences to creating very practical products and making them open to increase their added value and real benefits for the user.

At this occasion we asked Luka to share his plan for the upcoming year as Shuttleworth Fellow and his vision for the future of Institute IRNAS and manufacturing company Fabrikor.

Our exploration over the past two years in open hardware products and production highlighted a number of key learnings. Open hardware is a only component of the added value to the user - creating a fully functional, supported and complete products is most important and fosters its use, with the open component being an additional benefit for all the parties involved.

Thus we have shifted the narrative from the concept of open as such into very practical outcomes for the user:

-

Total ownership allows full use and repair of existing products as a complete insight into operation is available. Open hardware is today the best way to enable it.

-

Future proof devices are designed and documented such that users are empowered to innovate, explore and upgrade them outside the original specification. The lifespan of devices is extended, their reuse encouraged and their open hardware documentation an enabling component in communication between all parties involved.

-

Collaborative design is simplified thorugh open hardware, bridging the gap between the development, manufacturing and use of a device, enabling evolution of the product to be optimal for everyone involved.

BENEFITS OF OPEN HARDWARE VALUES

Product development flow when enabled with open hardware benefits all parties involved as thought transparency holds everyone accountable and aligned with agreed values. We explore the benefits of adhering to open hardware values in the following workflow to best illustrate this.

Research: Testing an idea, checking its feasibility and trying out a number of solutions is best done when we can peek into a number of existing products and solutions, learning from each one of them to form our solution. When devices are open hardware, it becomes almost trivial to learn from them.

Prototyping: Building an operational prototype of hardware is an exciting step, significantly empowered with an open hardware systems ranging from Arduino, Raspberry Pi and a bulk of different small modules available online. This immense library of modular solutions, which enables rapid prototyping, is sometimes tedious due to poor documentation of some systems, but significantly faster and more cost effective then other options.

Development: Product development as such is a detailed process when aiming for product manufacturing, having an insight into how existing products are built enables the discovery of best practices, speeding up the development and educating developers in the process.

Manufacturing: Manufacturing a product is no different if open hardware or not, however for very specific products if manufacturing tools and machines are well documented and open, their maintenance and even modifications are straightforward and empowering for the manufacturers.

Sales and user support: The sales and support cycle of a product are largely independent of its open hardware status. Openness however makes direct understanding of the user and serviceability of the devices easier, but most importantly, empowers the communication with the developers to collaboratively identify the improvements, changes and features for the upcoming versions.

Following our learnings we are for the next year focusing on development of open hardware products at Institute IRNAS and their manufacturing at Fabrikor, together creating a complete workflow with our customers from the initial idea to the final product.

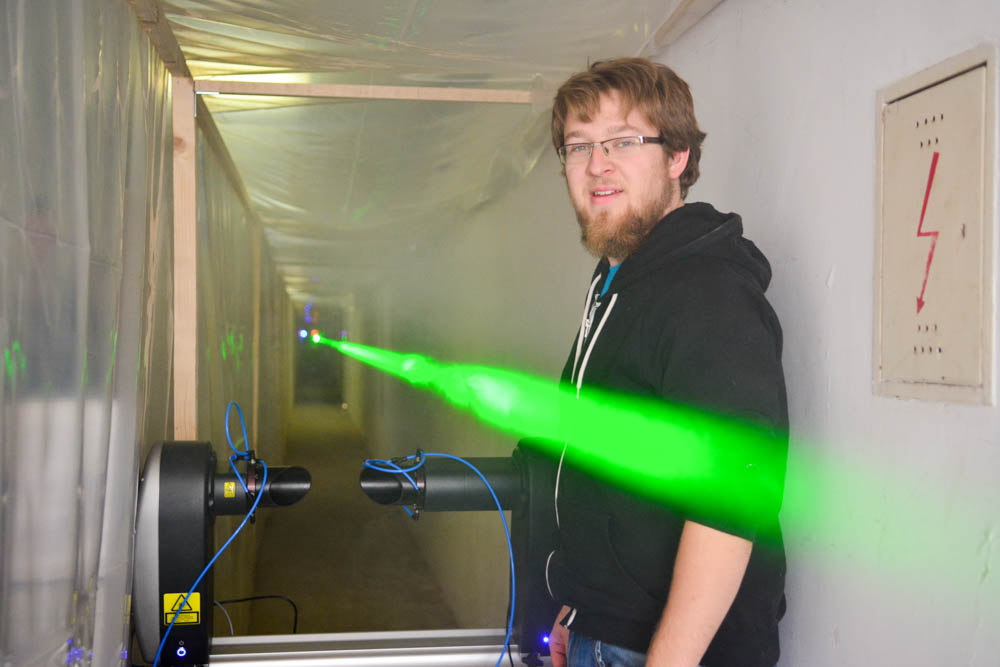

KORUZA

Our biggest project remains KORUZA, wireless optical communication system. So far, we’ve shown with KORUZA 1.0 that the technology works. Over 30 links were deployed worldwide in test networks like the one in Maribor and we have empowered universities and researchers worldwide to start exploring wireless optical technology. Due to a popular demand for an off-the-shelf product, we have made the next step and designed KORUZA Pro. It is smaller, more reliable and most importantly manufacturable at scale. With our expertise we have established in-house manufacturing to ensure the demands of the market are met in time and cost effective manner.

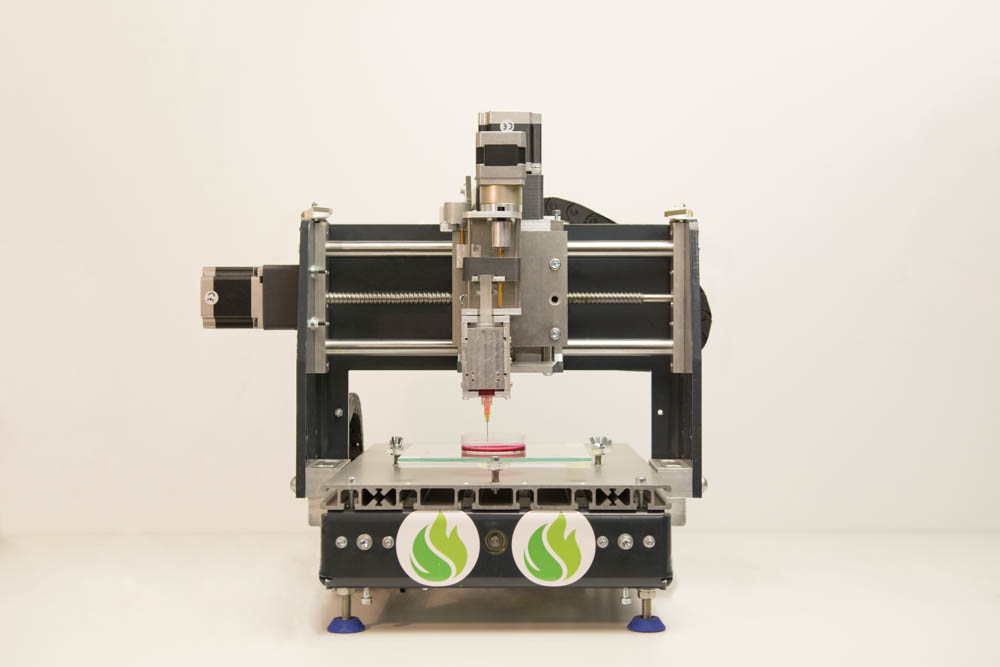

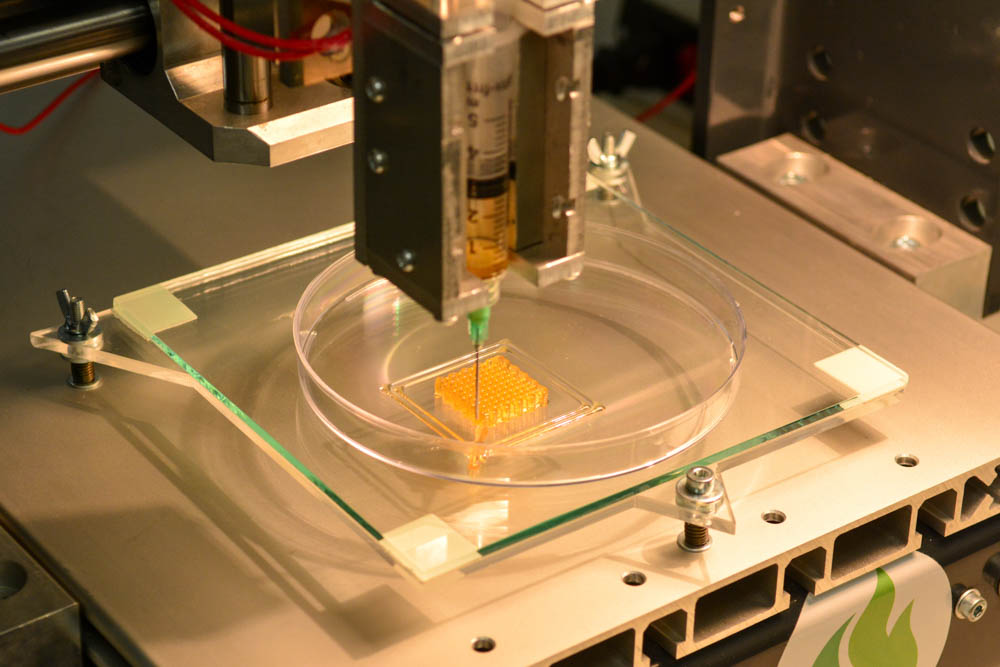

SYMBIOLAB & VITAPRINT

With open biolab Symbiolab we are changing how scientific research interacts with open hardware. Scientists are very good at their work and with the maker movement they are becoming more empowered to explore and create equipment on their own. But they often lack the engineering expertise and interest in making products. With our team we can very efficiently complement them and create open hardware products for specific applications, delivering user oriented features and manufacturing devices at Fabrikor. The primary focus for Symbiolab in 2017 remains the 3D bioprinting project Vitaprint.

IRNAS PhD PARTNERSHIP SCHEME

At IRNAS we believe that even geographical distribution of knowledge will be of extremely high importance in the future. The best way to approach this issue is through interinstitutional partnerships. One of the solutions we have found is the establishment of a PhD partnership scheme. The idea behind the programme is providing PhDs with a comperhensive experience of academic-industral collaboration as well as the skills and networks that accompany it. We are extremely proud of our first partnership with University College London (UCL), which has proved highly benefitial to both partners. Please, check this link for more information.

OPEN HARDWARE COLLABORATIONS

During past months we have also established partnerships with numerous open hardware projects within the Shuttleworth Foundation Fellowship and outside, which resulted in new projects for this year. We will actively collaborate on conservation technologies for Sea Turtles and other animals, open medical devices GliaX and environmental monitoring project Safecast.

With Institute IRNAS we provide high quality hardware and firmware development and with our company Fabrikor rapid prototyping and manufacturing service, helping our customers to overcome the gap between the research phase and the finished products, ready to enter the market. Our team of experts and the in-house manufacturing capabilities have already proven to be a fruitful combination for many projects.

And of course, also in 2017 we’ll stay open, since I believe this is the only way we can harvest the collective mind of this world and most effectively co-create a good future.