GoodEnoughCNC Mill

After we successfully built a working prototype of the plasma cutter, we took the next logical step and started to develop an open source, easy to build, multi purpose CNC milling machine. The main idea is the same - it has to be built using nothing more than standard hand tools (saw, drilling machine, screwdrivers,..), and locally available, easy to get components. It’s main use will be for carpentry. Because of that, machining area needs to be big enough to fit standard carpenter plywood sheet. The machine must also be able to cut sheets and small blocks of aluminium.

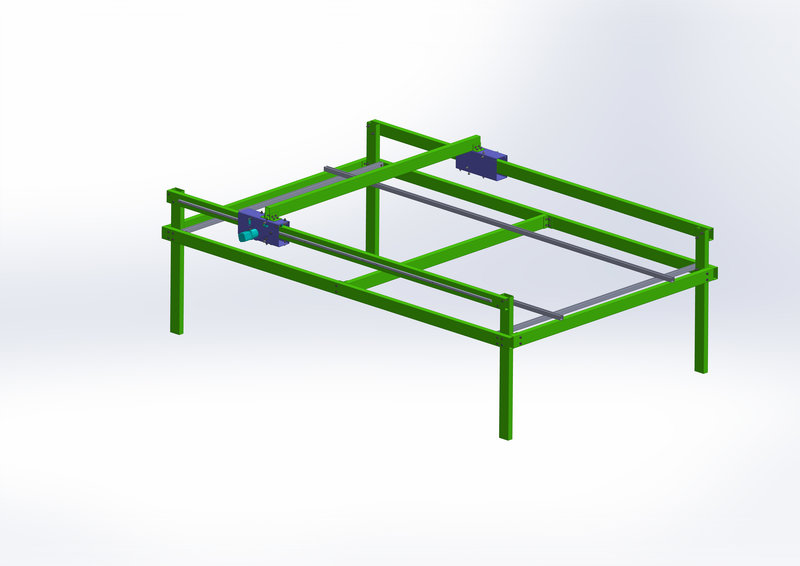

Because we confirmed the adequacy of the plasma cutter design, we decided to build on the existing structure, with the necessary adaptations. Instead of a basic profile 40mmx40mm , which serves as a guide for the x and y - axis , we decided to use 80mmx40mm , which will give the structure greater rigidity due to significantly increased dimensions x and y axes. Table size is 2900mmx1900mm, z - axis movement is 180mm.

As illustrated, the entire table of the CNC milling machine consists of four different profiles :

- 100x150x3 with the use for trolley on X and Y axis,

- 80x40x3 for airframes,

- c-section , which serves as a basis for the work-pieces,

- angles, used for bigger rigidity.

Because of the independence of advanced tools ( welding machine, …), the whole structure consists of screw connections.

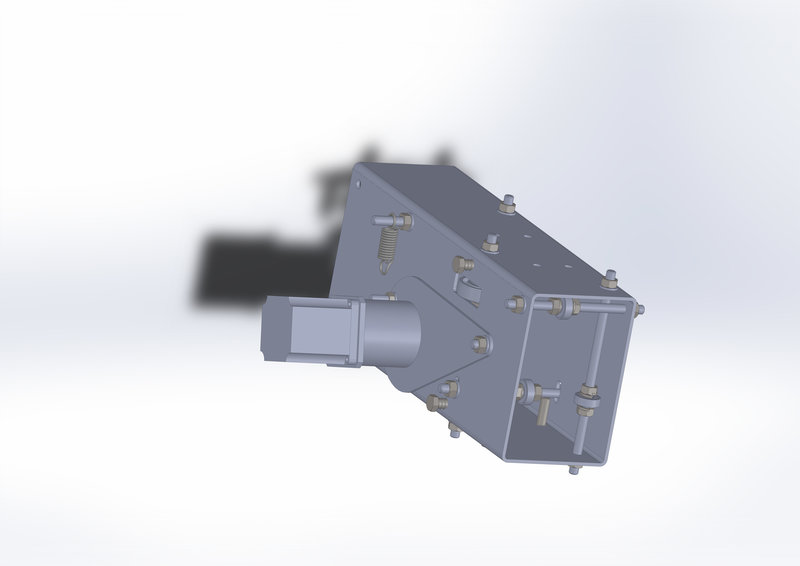

For trolleys we will use standard bearings 608ZZ and design that will allow the use of various stepper motors. Drive Y and X axis will be implemented using a rack module with gear on the motor with reducer . The latter change versus plasma cutter is needed, due to higher cutting forces that will work on the construction.